Symaga celebrates four decades of technical evolution, marked by a profound transformation in the design and manufacture of storage solutions. Since its inception, the company has been committed to constant innovation, adapting its processes to new technologies to offer increasingly precise and efficient structures.

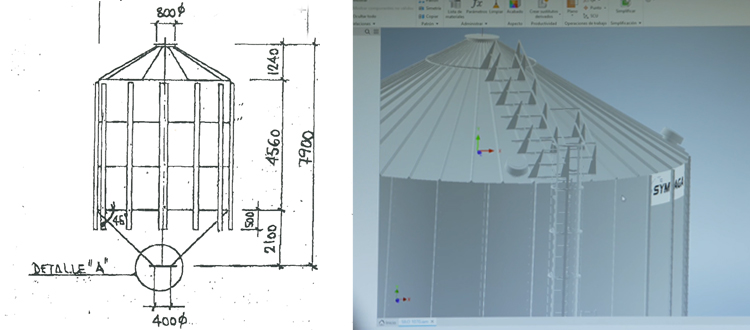

From the first hand-drawn plans to digital design

In the early years, Symaga silos were designed entirely by hand. As José María, the company’s CTO, recalls, “the plans were drawn by hand with a set square and a protractor, and the structural calculations were done with paper, pencil and a scientific calculator, applying high safety coefficients to compensate for uncertainty.

Every modification meant redoing all the calculations, which required great dedication and rigour.” Enrique del Río, Symaga’s first technician, laid the foundations for the Technical Department, producing the first designs with effort, ingenuity and a passion for engineering. His work marked the beginning of a journey that today is supported by state-of-the-art digital tools.

Constant evolution in technology and materials

Over the years, Symaga has integrated programmes such as AutoCAD, 3D design software, and finite element analysis. These tools allow real loads to be simulated and any changes to the design to be automatically validated, improving efficiency, reinforcing structural safety, and optimising steel consumption, thereby better controlling costs.

One of the key milestones has been the evolution of the materials used. Symaga was one of the first silo manufacturers to increase the zinc coating from Z450 to Z600 g/m² and introduce the ZM195 (zinc-magnesium) coating on roofs. In 2024, the quality of the steel used in the silo body was improved, replacing S350GD and HX500 with S450GD. This change has reduced the total weight of the silo, with consequent savings in logistics and assembly.

Overcoming technical challenges

Throughout its history, Symaga’s Technical Department has faced many challenges : from designing silos for extreme climates to integrating them into highly complex installations. The company’s commitment to exporting has driven the automation of production and the adaptation of its products to international regulations, as well as to very diverse climatic conditions, including specific requirements in terms of wind, snow, and seismic activity.

Digitalisation and Industry 4.0

David Recio, Technical Director at Symaga, points out that more than 15 technicians currently work with a fully digitalised system. ‘The designs are generated using specialised software and integrated directly with our production machines, which guarantees total traceability and precise manufacturing, minimising errors.’

Symaga has implemented Industry 4.0 processes, such as the MES system for production management and quality control, and an SGA system for storage optimisation, which have been fully operational since last year. The company has also had CNC technology on all its machines for more than 15 years, reinforcing its commitment to automation and efficiency.

Looking to the future : artificial intelligence and sustainability

With its sights set on the future, Symaga remains committed to digitalisation and artificial intelligence, both in design and predictive maintenance. Another major focus will be sustainability, through the optimisation of designs that reduce steel consumption and minimise waste and logistics costs.

In addition, the company is exploring new technologies such as BIM, with the aim of offering increasingly efficient, customised and intelligent storage solutions.

Over the last four decades, Symaga has provided technical solutions for every project. This evolution has been made possible thanks to the commitment, talent, and effort of our entire technical team, from Enrique to Álvaro. THANK YOU!